Casi di studio

Optidrives help create one of the most advanced rolling road test facilities in the UK

Problema

Accurate control of 12 fans simulating varying air movement cycles under strict conditions in vehicle test situations was required. The volumes of air would create real world and extreme external ambient conditions against the vehicle cells.

Soluzione

Optidrive Eco IP66 / Nema 4X variable frequency drives were chosen for their dedicated and accurate fan control system. The enclosures also ensured their durability in what can be extreme conditions within the rolling road test facility.

Stellar Engineering - Runway42

The UK’s latest and most sophisticated vehicle rolling road test facility is producing accurate data for super car engine calibration thanks to Invertek Drives Optidrive Eco variable frequency drives (VFD).

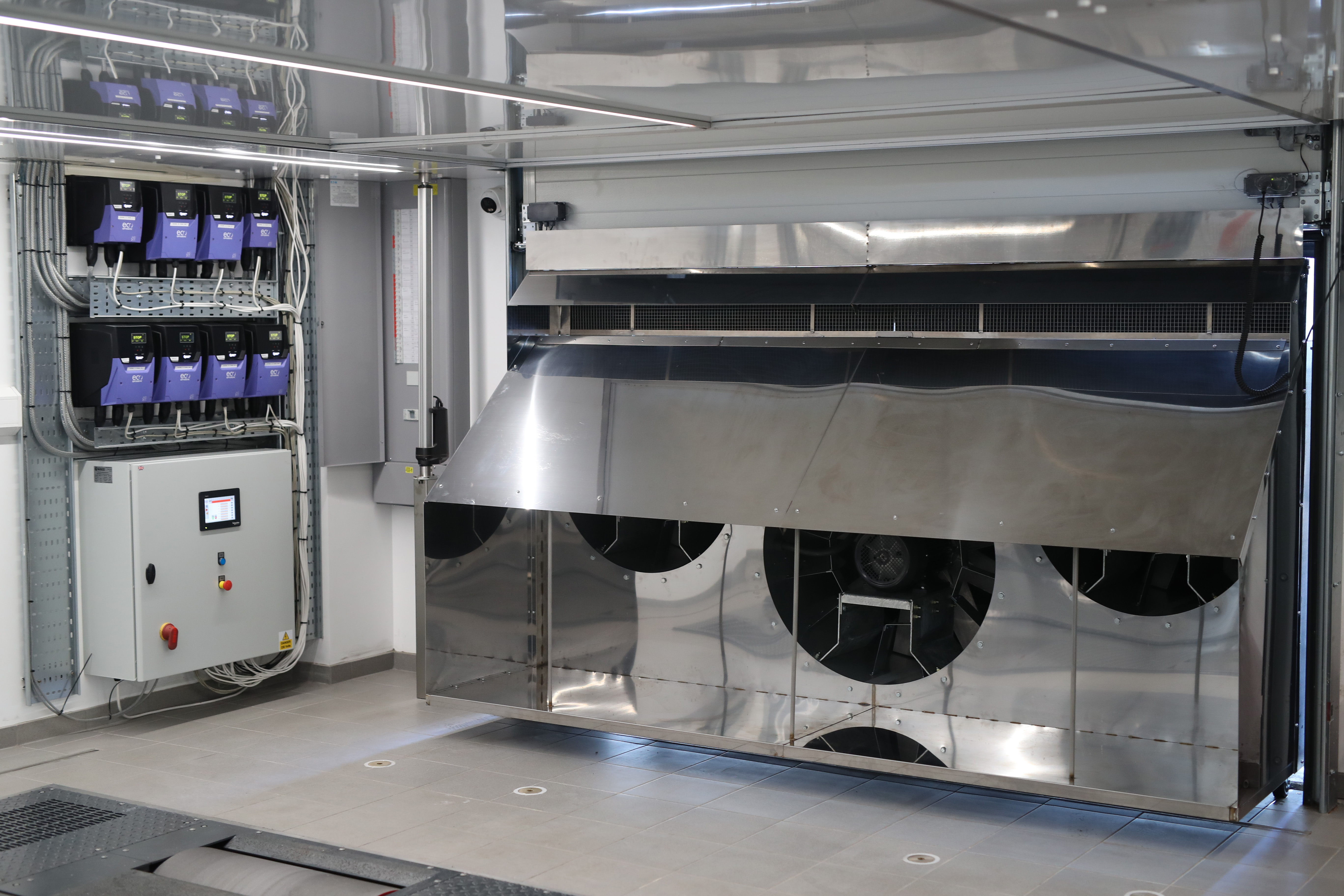

Fourteen high-output fans are housed in the test cell at Runway 42, part of the new Steller Technical Centre at Tingewick, Buckinghamshire.

The VFDs control 12 of the fans to simulate varying air movement cycles under strict conditions in vehicle test situations. The volumes of air create real world and extreme external ambient conditions against the vehicle cells.

Runway42 is part of Steller Engineering Ltd, a racing team and engineering company specialising in bespoke engine and gearbox calibrations for super, hyper and race cars. The high-powered vehicles are placed in the facility to undergo testing as part of the engine calibration process.

Optidrive Eco fan control

Twelve Optidrive Eco IP66 / NEMA 4X VFDs have been commissioned within the test facility. Engineers worked with Motor Control Warehouse, a sales partner of Invertek Drives in the UK, who supplied the drives and designed the control panel.

The drives included six Size 3, 7.5kW, 400V; four Size 2, 4kW, 400V and two Size 2, 1.5kW, 400V Optidrive Eco VFDs.

“This is a new facility and the thinking behind how to design the systems in place was totally different to any similar outfit currently available,” said Max Daymond of Steller Engineering Ltd.

“We wanted to create a system whereby we could accurately control and monitor a system of high-output fans at varying duty cycles simultaneously for short periods of time under a relatively strict set of conditions. This included monitoring and adjusting cell pressure against external ambient conditions to obtain as close to ambient values as possible whilst flowing a considerable volume of air.”

Optidrive was the choice VFD

He said the quality of Invertek’s Optidrive VFDs was a key reason for choosing them.

“Invertek supplied a range of highly versatile, high quality and aesthetically pleasing drives through Motor Control Warehouse that allowed us to control the fan speeds quickly, accurately and with as minimal current draw as possible - as this was a primary concern,” said Max.

“The installed system manages to accurately control the fans individually and as banks in an efficient manner under demanding environments.”

He added: “The outcome has been an integrated system that accurately controls several banks of fans to create a unique, bespoke and highly flexible air movement system which has already proven to be a fundamental part of our exciting new facility.

“We’re really pleased to be working alongside Invertek and Motor Control Warehouse to create one of the most advanced testing facilities in the UK.”

Designed specifically for fan control

Optidrive Eco HVAC VFDs are designed specifically for fan and pump control. They provide accurate speed control that helps achieve significant savings in energy and costs. In the case of Runway42, the ability to accurately control fan speed was paramount.

Gez Evans of Motor Control Warehouse said IP66 / NEMA 4X drives were needed due to the extreme conditions within the test cell. They would also need an emergency stop system.

IP66 / NEMA 4X enclosures

“The IP66 enclosure protected drives were mounted adjacent to the main control panel, with control from an HMI and PLC. The system also has an E-Stop facility.

"We designed and built a control panel with an HMI and PLC to provide the control needed. The Optidrives were fitted external to the panel and controlled over Modbus. A safety relay inside the panel was used to switch the drives’ STO under E-Stop condition."

He added: "Custom software was created to control all of the fans, with a seven-inch HMI with user friendly graphical interface. The system also provided remote access, data logging of the running currents and output frequencies of the 14 drives, and the ability to send recipes to the PLC from PCs on the Steller network."

More information about Runway42 can be found at www.runway42.co.uk.