Cooling Matters

Article 25

Semiconductors don’t like to get too hot; some will work up to 150 oC or even 175oC, but most give up the ghost at 125oC. Incidentally, they don’t like being too cold either, that’s why variable frequency drives and similar equipment need some cubicle heaters if the temperature drops much below -10oC.

But keeping equipment cool is usually the biggest challenge. Put a drive in a cubicle along with a few other drives and some warm electronics, close the door, install it in a nice warm factory in India say, and then step back and wait for the over-temperature trips. How do we avoid this?

Well, it starts with the drive designer. The control electronics needs a little cooling of course, but the power semiconductors (the diodes and IGBTs) will give off significant heat as they switch and handle the high currents and voltages. So they are attached to a heatsink, and the heatsink is often provided with a fan. On Invertek drives the fan switches on only when the drive gets hot, so the fan life is maximised. Why? Well, the fan has a limited life, dependent on the bearings. On a good fan this will be about 40,000 hours – about five years or so continuous running, so saving fan time (and recording it, as Invertek drives also do) is worthwhile. So with the right heatsink and cooling arrangement the power components are kept cool, even at full load.

It’s also important to cool the electrolytic capacitors, as they get warm and can overheat. So they need to be positioned in the airflow as well. Some Eco drives no longer use electrolytic capacitors, increasing efficiency and reducing losses.

This is all very well for an IP20 drive, which can have air flowing through it, but an IP66 drive is sealed, so cooling gets harder. The solution is to have a large, external, naturally cooled heatsink and plenty of room inside the drive with a small ‘stirring’ fan making sure there are no hotspots building up.

IP20 drives are usually designed for a maximum ambient temperature of 50 oC, while IP66 drives are limited to 40 oC. However, drives can usually be operated at higher temperatures if they aren’t run at full load. Consult your supplier before you buy the drive if you want to do this.

Incidentally, the higher the switching frequency, the higher the losses, so higher power drives tend to have a lower switching frequency to keep losses down. If you increase the switching frequency you may need to derate the drive; again, consult the factory.

All Invertek drives are protected against high temperatures; there are temperature sensors built into the power module, and others monitor the control board temperature. The drive will give a warning, and then trip if the temperature approaches a dangerous level.

Large drives require more cooling. Large, noisy fans are needed for high power drives, and for drives over (say) 500kW, water cooling becomes a useful option.

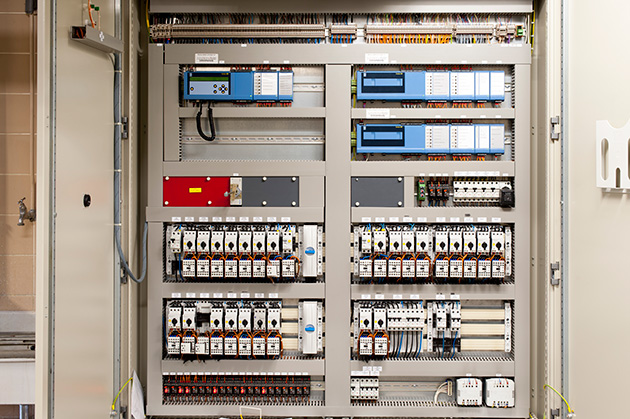

When it comes to installation, the machine builder or cubicle designer must also take responsibility for cooling. IP20 units are designed to be mounted in cabinets, or in similar areas in machines. But heat can build up inside these areas, especially if there is other heat dissipating equipment in the same cubicle. You can calculate the temperature rise in an unventilated steel cubicle using the formula:

Trise = Ploss/(5.5 x A)

Where A is the total exposed area of the cabinet in square metres, and Ploss is the power loss for all equipment in the cabinet. If you ventilate the cubicle with a fan, the temperature rise is dependent on the airflow:

Trise = (0.053 x Ploss)/F

Where F is the air flow in cubic metres /minute.

All this is fine if you know the total heat loss within the cubicle; usually that’s difficult to estimate. For drives, a rule of thumb is that the losses from a drive are typically 3% of the rated power.

Remember, you’re calculating the temperature rise for the air inside the cubicle; if the external temperature is, say 35 oC, you haven’t got much headroom. There are plenty of installations designed and tested in the cold of western Europe that don’t last long once they reach the Middle East or Asia (although many plant rooms there are air conditioned now).

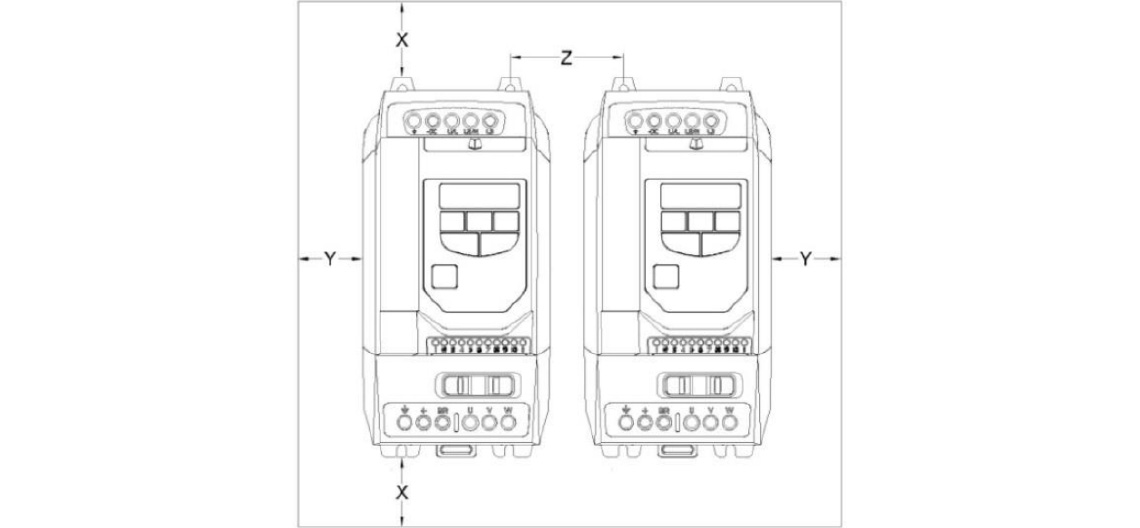

Take care inside the cubicle as well. There should be space at the bottom and top of the drive to allow free airflow through the drive; don’t block it with cable ducting for example. Many drives can be mounted side by side, but some require a gap to allow venting at the side; check in the handbook, as shown in Figure 2.

Some drives are designed so you can stick the heatsink out of the back of the cubicle to get better cooling and reduce temperature rise inside. Others can be supplied without a heatsink, relying on the installer to provide a ‘cold plate’ for cooling. These drives are mainly intended for machine builders who want to minimise space.

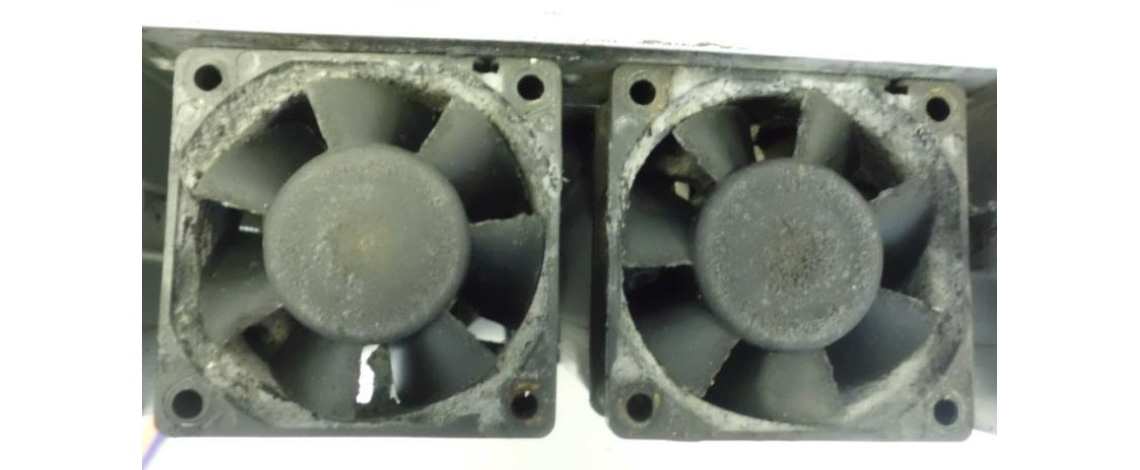

Variable speed drives generally rely on a supply of cool, clean air to maintain a safe temperature. Any dirt, dust or liquid can damage a drive (in particular IP20 drives of course), but it can also lead to overheating as it blocks airflow over heatsinks and slows down or stalls fans as dirt builds up on the blades.

If you’re using a fan to cool the cubicle, it may well need a filter that will require regular cleaning, so think about the amount and nature of the contamination entering the cubicle.

IP66 drives are designed for installation outside of a cubicle or even (in the case of Invertek’s latest units) outside. However, they can still suffer from blocked heatsinks and inhibited airflow due to dirt or poor installation. Worth checking occasionally.

All these cooling designs and calculations are based on the amount of air we have around us. Climb to the top of a mountain, or visit Mexico City (among others) and there is less air to breathe, as well as for cooling. Drives are usually fully rated only up to 1000m above sea level, so installations in ski lifts, Copper mines in the Andes (over 3000m), or anywhere in Mexico City (2250m) require derating – roughly 10% for every 1000m above the base 1000m, but check with your supplier. And yes, Ski lifts are pretty cold in winter, but they work in the summer as well....