Especificaciones del Optidrive Coolvert

| KW | HP | Amperios | Tamaño | Model Code |

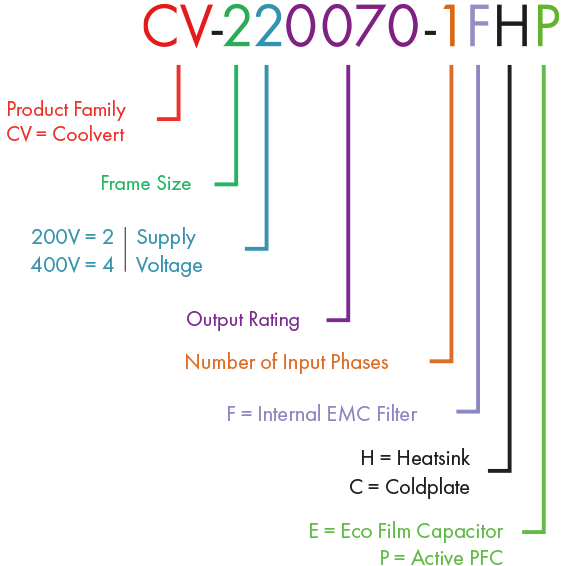

Product Family |

Tamaño del marco |

Voltage Code |

Power Rating Code |

Number of Input Phases |

Filtros EMC |

Heatsink/Coldplate |

Power Technology |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 200 – 240V ± 10% 1 Phase Input |

1.5 | 2 | 7.0 | 2 | CV | - | 2 | 2 | 0070 | - | 1 | F | # | P | |||

| 3 | 4 | 12 | 2 | CV | - | 2 | 2 | 0012 | - | 1 | F | # | P | ||||

| 4 | 5.5 | 16.0 | 2 | CV | - | 2 | 2 | 0160 | - | 1 | F | # | P | ||||

| 5.5 | 7.5 | 20.0 | 2 | CV | - | 2 | 2 | 0200 | - | 1 | F | # | P | ||||

| 380 – 480V ± 10% Entrada monofásica y trifásica |

5.5 | 7.5 | 14 | 2 | CV | - | 2 | 4 | 0140 | - | 3 | F | # | E | |||

| 7.5 | 10 | 18 | 2 | CV | - | 2 | 4 | 0180 | - | 3 | F | # | E | ||||

| 11 | 15 | 24 | 2 | CV | - | 2 | 4 | 0240 | - | 3 | F | # | E | ||||

| 15 | 20 | 30 | 3 | CV | - | 3 | 4 | 0300 | - | 3 | F | # | E | ||||

| 18.5 | 25 | 39 | 3 | CV | - | 3 | 4 | 0390 | - | 3 | F | # | E | ||||

| 22 | 30 | 46 | 4 | CV | - | 4 | 4 | 0460 | - | 3 | F | # | E | ||||

| 30 | 40 | 58 | 4 | CV | - | 4 | 4 | 0580 | - | 3 | F | # | E |

Model Code Guide

Tamaño y peso

Heatsink Version (dimensions in mm)

NOTE: The Heatsink Version can be conventionally mounted on the backplate of a panel using the optional panel mounting kit (sold separately)

| A | B | C | D | E | F | G | H | J | K | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | ||

| Size 2 | 226.3 | 8.9 | 215.2 | 8.5 | 201.4 | 7.9 | 165.3 | 6.5 | 144.8 | 5.7 | 182 | 7.2 | 177 | 6.96 | 71.7 | 2.82 | 104.4 | 4.11 | 104.4 | 4.11 | |

| Size 3 | 277.5 | 10.9 | 262.6 | 10.3 | 247.2 | 9.7 | 193.6 | 7.6 | 168.9 | 6.6 | 224 | 8.8 | 200.3 | 7.9 | 84.3 | 3.3 | 116 | 4.6 | 116 | 4.6 | |

| Size 4 | 310 | 12.2 | 336 | 13.3 | 364 | 14.3 | 239.5 | 9.4 | 150 | 5.9 | 291.5 | 11.5 | 230.6 | 9.1 | 98 | 3.9 | 133 | 5.2 | 133 | 5.2 | |

Coldplate Version (dimensions in mm)

| A | B | C | D | E | F | G | H | J | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | ||

| Size 2 | 226.3 | 8.9 | 215.2 | 8.5 | 201.4 | 7.9 | 165.3 | 6.5 | 90 | 3.5 | 37.7 | 1.48 | 113.9 | 4.48 | 104.4 | 4.11 | 9.5 | 0.37 | |

Especificaciones técnicas

| Input Ratings | Clasificación de las entradas | 200 – 240V ± 10% 380 – 480V ± 10% |

| Frecuencia de suministro | 48 – 62Hz | |

| Desplazamiento Factor de potencia | > 0.98 | |

| Desequilibrio de fases | 3 % máximo permitido | |

| Corriente de entrada | < corriente nominal | |

| Ciclos de potencia | 120 por hora como máximo, espaciados uniformemente |

| Clasificación de salida | Potencia de salida | 200V: 7.0A to 20A 400V: 14A to 24A |

| Capacidad de sobrecarga | 130% durante 10s segundos | |

| Frecuencia de salida | 0 – 500Hz | |

| Tiempo de aceleración | 0.01 – 600 segundos | |

| Tiempo de desaceleración | 0.01 – 600 seconds | |

| Eficiencia típica | > 98% |

| Condiciones ambientales | Temperatura | Almacenamiento: −40 to 70°C En funcionamiento: −20 to 60°C |

| Altitude |

Hasta 1000 m s. n. m. sin reducción de potencia Hasta 2000 metros como máximo, con aprobación UL Hasta un máximo de 4000 m (no UL) |

|

| Humedad | 95 % máximo, sin condensación | |

| Vibración | Cumple la norma EN61800-5-1 |

| Carcasa | Protección de ingreso (IP) | Front IP20 Rear (Through Panel Mounting) IP55 |

| Coated PCBs | Designed for operation in 3S2/3C2 environments according to IEC 60721-3-3 |

| Programación | Modbus RTU (RS485) | Modbus RTU on Pluggable terminals and through RJ45 port |

| PC Tools | PC Tools software for Diagnostics and parameter configuration (RJ45 port only) | |

| Teclado | Optional Remote Keypad with TFT display for diagnostic and programming | |

| Aplicación para smartphone | Optitools Mobile |

| Especificación de control | Método de control | 200 – 240V ± 10% 380 – 480V ± 10% |

| Frecuencia PWM | 4 – 32kHz | |

| Modo de parada | Rampa hasta la parada, Marcha en inercia hasta la parada | |

| Frecuencia de Salto | 2 skip frequencies, user adjustable | |

| Modos de control |

Modbus RTU (RS485) Terminal Control Digital / Analogue Terminal Control PI mode Master / Slave Mode |

| Par de seguridad desactivado (STO) | IEC 61800-5-2:2016 | SIL 3 |

| EN ISO 13849-1:2015 | PL “e” | |

| EN 61508 (Part 1 to 7): 2010 | SIL 3 | |

| EN 60204-1: 2006 & A1: 2009 | Cat 0 | |

| EN 62061: 2005 & A2: 2015 | SIL CL 3 | |

| Independent Approval | TUV Rheinland* |

| Características de la aplicación | Control PI | Controlador PI interno |

| Demagnetisation Protection | Configurable over-current trip threshold for greater protection against demagnetisation of the motor | |

| Start-up Profile | Three stage configurable start-up profile to ensure lubrication and increased compressor lifetime | |

| Start/Stop Blocking Features | Configurable Minimum On Time, Minimum off Time and Minimum Re-Start Delay to reduce oil migration and maximise compressor lifetime | |

| Serial Communications Loss Fall-Back Speed | The ability to configure the drive to run at a ‘safe’ speed in the even of a loss of serial communication. Can prevent total loss of operation whilst maintaining minimum process demands |

| Mantenimiento y diagnóstico | Memoria de fallos | Últimos 3 disparos almacenados con marca de tiempo |

| Registro de datos | Registro de datos antes del disparo para fines de diagnóstico: Corriente de salida Temperatura de la unidad Tensión del bus de CC |

|

| Monitorización | Medidor de horas de funcionamiento kWH |

| Conformidad | The Coolvert product range conforms to the relevant safety provisions of the following council directives: 2014/30/EU (EMC), 2014/35/EU (LVD), 2006/42/EC (Machinery Directive), 2011/65/EU (RoHS 2) and 2009/125/EC (Eco-design) | |

| Design and manufacture is in accordance with the following harmonised European standards: | ||

| BSEN 61800-5-1: 2007 & A1: 2017 | Adjustable speed electrical power drive systems. Safety requirements. Electrical, thermal and energy. | |

| BSEN 61800-3:2018 | Adjustable speed electrical power drive systems. Part 3: EMC requirements and specific test methods (IEC 61800-3:2017). | |

| BSEN 61800-9-2:2017 | Adjustable speed electrical power drive systems. Part 9-2: Ecodesign for power drive systems, motor starters, power electronics and their driven applications – Energy efficiency indicators for power drive systems and motor starters (IEC 61800-9-2:2017). | |

| BSEN 60529: 1992 & A2: 2013 | Specifications for degrees of protection provided by enclosures | |

| UL 61800-5-1 | cUL Listed * cUR Recognised for the coldplate variants * |

|

| BSEN 61000-3-12: 2011 | Electromagnetic compatibility (EMC) - Part 3-12: Limits - Limits for harmonic currents produced by equipment connected to public low voltage systems with input current >16 A and ≤ 75 A per phase | |

|

BSEN 61000-3-2:2019 (single phase input variants only) |

Electromagnetic compatibility (EMC).Limits - Limits for harmonic current emissions (equipment input current ≤16 A per phase) | |

*Pending