The critical role of variable frequency drives in reducing energy consumption

Optidrive variable frequency drives help match motor speeds to the exact requirements of each application, saving energy and providing improved control.

With the global economy predicted to more than double by 2050 the need to balance economic growth with a reduction in energy consumption and carbon emissions is critical.

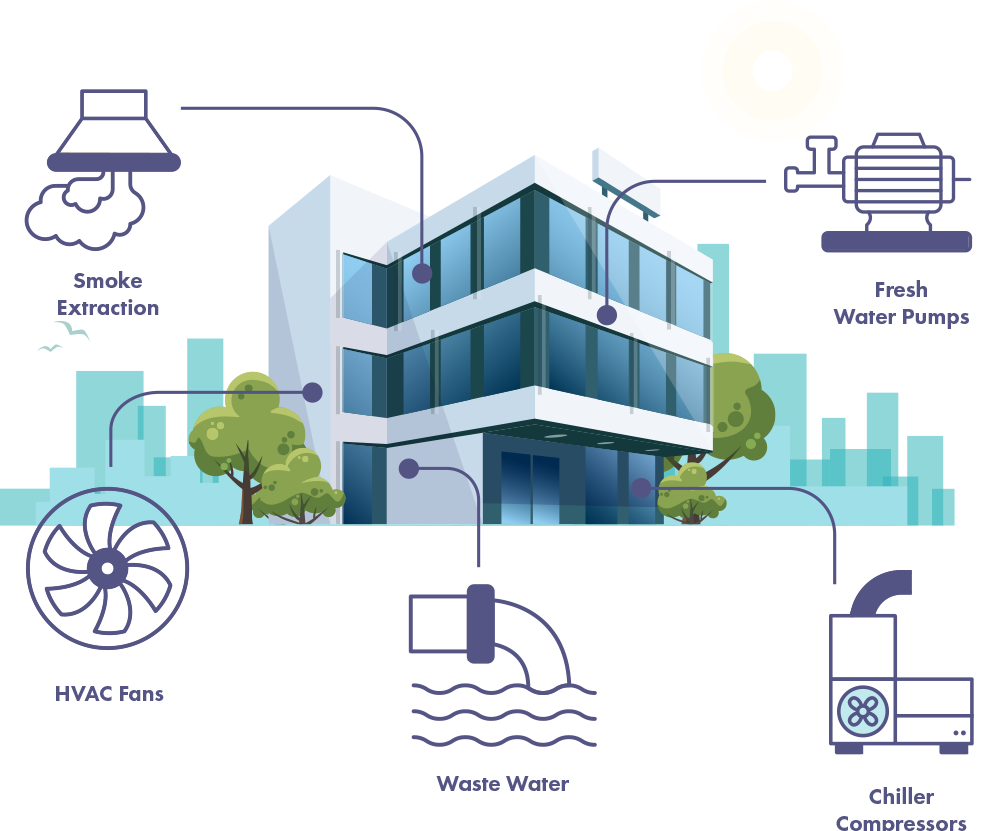

With 70% of industrial electricity and 38% of electricity in buildings being used by electric motors, according to the IEA (International Energy Agency), these two sectors are primary targets for energy use reduction with variable frequency drives.

Energy Savings Calculator

OptidriveTM variable frequency drives save energy, money and time.

Estimate your potential energy savings, CO2 emissions and financial savings.

Global energy efficiency standards for motors

All over the world, Governments have introduced energy savings targets and are putting legislation and regulations in place to ensure they are met.

At the heart of these regulations are the International Efficiency (IE) standards, designed to promote higher energy efficiency to reduce the energy consumption of low voltage AC motors. But even with the significant energy savings that can be achieved by upgrading to a more efficient motor, even more savings are available by combing this with a variable frequency drive.

As a variable frequency drive is used to adjust the speed and torque of a motor to match the systems load requirements, we can ensure the motor only runs as fast and as long as is required. No matter how energy efficient the motor this means there are always significant additional energy savings to be made.

Five levels of motor efficiency

International Efficiency (IE) standards stipulate the energy efficiency of low voltage AC motors. These IE codes serve as a reference for governments who specify the efficiency levels for their minimum energy performance standards (MEPS).

Invertek Drives’ variable frequency drives are all built to exceed the requirements of IE2 as required by the Ecodesign Directive.

Ecodesign – energy efficiency standards for motors and variable frequency drives

The European Union (EU) Ecodesign Directive provides consistent EU-wide rules for improving the environmental performance of products, from household appliances to engineering products. The target is to avoid 40 million tonnes of CO2 by 2030.

The latest Ecodesign Regulation (EU) 2019/1781 came into effect in October 2019 and now includes variable frequency drives (VFDs) along with a wider range of motors. A second phase, which expands the scope of the regulation and increases the requirements for motors, will commence on 1st July 2023.

Find the energy efficient data for your driveOur Drive for Sustainability

At the UN Sustainable Development Goals Summit in September 2019, world leaders called for a Decade of Action. They set out the economic, social, and environmental challenges of generating prosperity whilst protecting the planet, headed by the biggest challenge of all: Climate change.

Whilst goal 13 calls for urgent action to combat climate change and its impacts, all 17 of the goals influence sustainable development.

Achieving the climate goals of the Paris Agreement to cap the increase in global temperature to 1.5°C - requires us to be acting now on improving energy efficiency.

Science based targets; industry expertise; dedication to energy efficiency in every aspect of our operations and the solutions we provide. These are the essential building blocks for a greener, more sustainable future.

We are committed to acting responsibly in the world in which we operate. Our drive for a cooler planet began nearly 25 years ago with a range of variable frequency drives that reduce energy used by electric motors in applications around the world.

We continue to dedicate our energies to reducing carbon emissions. From electric vehicles to sustainable infrastructure and processes, we are taking steps towards a greener future.