Optidrive P2 Features

High performance, variable frequency, excellent usability and flexible to meet the needs of your application.

150% overload for 60 seconds

200% overload for 4 seconds

Industrial heavy duty rating for every mode

- on board as standard

-

Sensorless Vector Control

Up to 200% torque from zero speed ensures reliable starting and accurate speed control under all load conditions.

-

PM Motor Control

Future proof. Allows upgrade to the latest generation of high efficiency permanent magnet motors.

-

Built-in EMC Filter

An internal filter in every Optidrive P2 saves cost and time for installation.

-

Integral Brake Transistor

Saves space, cost and time for installation.

-

Sensorless Vector Control for all Motor Types

- Induction Motors (IM)

- Permanent Magnet Motors (PM)

- Brushless DC Motors (BLDC)

- Synchronous Reluctance Motors (SynRM)

- Line Start PM Motor (LSPM)

-

Options & Software

A range of external EMC filters, brake resistors, input chokes and output filters are available.

Installation Options -

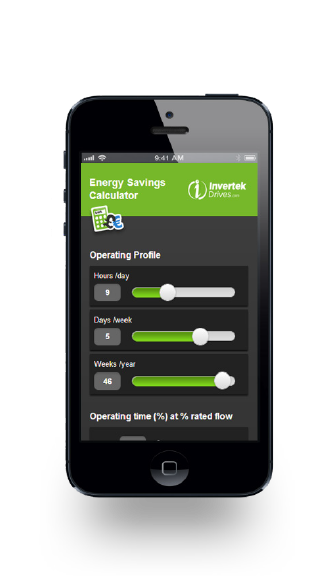

Optistick Smart Compatible

Rapid commissioning tool.

Enclosure Options

Optidrive P2 is available in a range of IP20, IP55 & IP66/NEMA 4X enclosures.

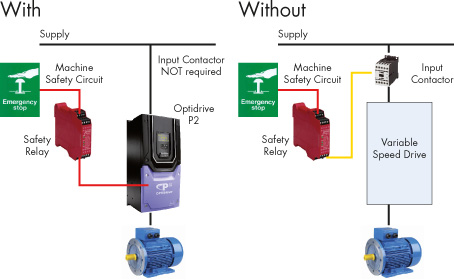

Safe Torque Off

Optidrive P2 features a safe torque off function to allow simple integration into machine critical safety circuits.

- Simple machine design reduces component costs, saves panel space and minimises installation time.

- Faster shut down and reset procedures reduce system maintenance time.

- Better safety standard compared to mechanical solution.

- Better motor connection. Single cable with no interruption.

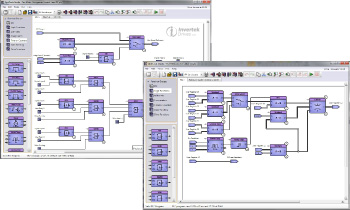

Simple PLC Functionality

A wide range of function types available including:

- Programmable logic functions

- Comparators

- Timers

- Mathematical functions

- Drive specific functions

All blocks can be easily combined to create flexible programs.

Programs can be protected to prevent unauthorised copying.

Complete control over the drive including all inputs and outputs.