Optidrive Coolvert Specification

| kW | HP | Amps | Size | Model Code |

Product Family |

Frame Size |

Voltage Code |

Power Rating Code |

Number of Input Phases |

EMC Filter |

Heatsink/Coldplate |

Power Technology |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 200 – 240V ± 10% 1 Phase Input |

1.5 | 2 | 7.0 | 2 | CV | - | 2 | 2 | 0070 | - | 1 | F | # | P | |||

| 3 | 4 | 12 | 2 | CV | - | 2 | 2 | 0120 | - | 1 | F | # | P | ||||

| 4 | 5.5 | 16.0 | 2 | CV | - | 2 | 2 | 0160 | - | 1 | F | # | P | ||||

| 5.5 | 7.5 | 20.0 | 2 | CV | - | 2 | 2 | 0200 | - | 1 | F | # | P | ||||

| 380 – 480V ± 10% 3 Phase Input |

5.5 | 7.5 | 14 | 2 | CV | - | 2 | 4 | 0140 | - | 3 | F | # | E | |||

| 7.5 | 10 | 18 | 2 | CV | - | 2 | 4 | 0180 | - | 3 | F | # | E | ||||

| 11 | 15 | 24 | 2 | CV | - | 2 | 4 | 0240 | - | 3 | F | # | E | ||||

| 15 | 20 | 30 | 3 | CV | - | 3 | 4 | 0300 | - | 3 | F | # | E | ||||

| 18.5 | 25 | 39 | 3 | CV | - | 3 | 4 | 0390 | - | 3 | F | # | E | ||||

| 22 | 30 | 46 | 4 | CV | - | 4 | 4 | 0460 | - | 3 | F | # | E | ||||

| 30 | 40 | 58 | 4 | CV | - | 4 | 4 | 0580 | - | 3 | F | # | E | ||||

| 37 | 45 | 65 | 5 | CV | - | 5 | 4 | 0650 | - | 3 | F | # | E | ||||

| 40 | 50 | 75 | 5 | CV | - | 5 | 4 | 0750 | - | 3 | F | # | E |

Replace # in model code with colour-coded option

Heatsink/Coldplate

-

H

Heatsink

version -

C

Coldplate

version

Dimensions

Heatsink Version (dimensions in mm)

| A | B | C | D | E | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | in | mm | in | mm | in | mm | in | mm | in | ||

| Size 2 | 226 | 8.9 | 165 | 6.5 | 177 | 7.0 | 72 | 2.8 | 104 | 4.1 | |

| Size 3 | 278 | 10.9 | 194 | 7.6 | 200 | 7.9 | 84 | 3.3 | 116 | 4.6 | |

| Size 4 | 364 | 14.3 | 240 | 9.4 | 231 | 9.1 | 98 | 3.9 | 133 | 5.2 | |

| Size 5 | 364 | 14.3 | 240 | 9.4 | 240 | 9.4 | 107 | 4.2 | 133 | 5.2 | |

NOTE: The Heatsink Version can be conventionally mounted on the backplate of a panel using the optional panel mounting kit (sold separately)

Coldplate Version (dimensions in mm)

| A | B | C | |||||

|---|---|---|---|---|---|---|---|

| mm | in | mm | in | mm | in | ||

| Size 2 | 226 | 8.9 | 165 | 6.5 | 114 | 4.5 | |

| Size 3 | 278 | 10.9 | 194 | 7.6 | 126 | 5.0 | |

| Size 4 | 364 | 14.3 | 240 | 9.4 | 140 | 5.5 | |

| Size 5 | 364 | 14.3 | 240 | 9.4 | 141 | 5.5 | |

Technical Specifications

| Input Ratings | Supply Voltage | 200 – 240V ± 10% 380 – 480V ± 10% |

| Supply Frequency | 48 – 62Hz | |

| Displacement Power Factor | > 0.98 | |

| Phase Imbalance | 3% Maximum allowed | |

| Inrush Current | < rated current |

| Output Ratings | Output Power | 200V: 7.0A to 20A 400V: 14A to 75A |

| Overload Capacity | 130% rated current for 10s | |

| Output Frequency | 0 – 500Hz | |

| Acceleration Time | 0.01 – 600 seconds | |

| Deceleration Time | 0.01 – 600 seconds | |

| Typical Efficiency | > 98% |

| Ambient Conditions | Temperature | Storage: −40 to 70°C Operating: −20 to 60°C |

| Altitude |

Up to 1000m ASL without derating Up to 2000m maximum |

|

| Humidity | 95% Max, non condensing | |

| Vibration | Conforms to EN61800-5-1 |

| Enclosure | Ingress Protection (IP) | Front IP20 Rear (Through Panel Mounting) IP55 |

| Coated PCBs | Designed for operation in 3S2/3C2 environments according to IEC 60721-3-3 |

| Programming | Modbus RTU (RS485) | Modbus RTU on Pluggable terminals and through RJ45 port |

| PC Tools | PC Tools software for Diagnostics and parameter configuration (RJ45 port only) | |

| Keypad | Optional Remote Keypad with TFT display for diagnostic and programming | |

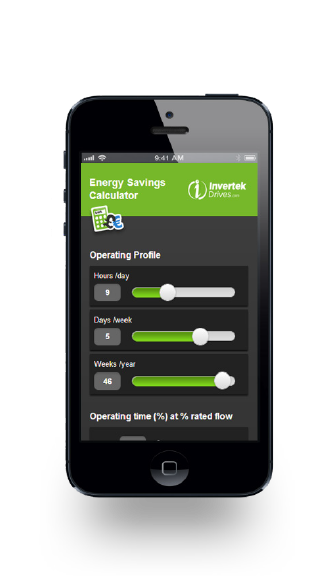

| Smartphone app | Optitools Mobile |

| Control Specification | PWM Frequency | 4 – 32kHz |

| Control Modes |

Modbus RTU (RS485) Terminal Control Digital / Analogue Terminal Control PI mode Master / Slave Mode |

| Safe Torque Off (STO) | IEC 61800-5-2:2016 | SIL 3 |

| UL 61800-5-2 : 2022 | SIL 3 | |

| Independent Approval | TUV Rheinland / UL |

| Maintenance & Diagnostics | Fault Memory | Last 3 trips stored with time stamp |

| Data Logging | Logging of data prior to trip for diagnostic purposes | |

| Monitoring | Hours Run Meter kWH |

| Conformance | The Coolvert product range conforms to the relevant safety provisions of the following council directives: 2014/30/EU (EMC), 2014/35/EU (LVD), 2006/42/EC (Machinery Directive), 2011/65/EU (RoHS 2) and 2009/125/EC (Eco-design) | |

| Design and manufacture is in accordance with the following harmonised European standards: | ||

| BSEN 61800-5-1: 2007 & A1: 2017 | Adjustable speed electrical power drive systems. Safety requirements. Electrical, thermal and energy. | |

| BSEN 61800-3:2018 | Adjustable speed electrical power drive systems. Part 3: EMC requirements and specific test methods (IEC 61800-3:2017). | |

| BSEN 61800-9-2:2017 | Adjustable speed electrical power drive systems. Part 9-2: Ecodesign for power drive systems, motor starters, power electronics and their driven applications – Energy efficiency indicators for power drive systems and motor starters (IEC 61800-9-2:2017). | |

| BSEN 60529: 1992 & A2: 2013 | Specifications for degrees of protection provided by enclosures | |

| UL 61800-5-1 | cUL Listed cUR Recognised for the coldplate variants |

|

| BSEN 61000-3-12: 2011 | Electromagnetic compatibility (EMC) - Part 3-12: Limits - Limits for harmonic currents produced by equipment connected to public low voltage systems with input current >16 A and ≤ 75 A per phase | |

|

BSEN 61000-3-2:2019 (single phase input variants only) |

Electromagnetic compatibility (EMC).Limits - Limits for harmonic current emissions (equipment input current ≤16 A per phase) | |